Unlike when using commercial materials, and you can just open a bag of powdered ingredients, there is a long process involved in preparing rocks for use in glazes. This marks the second stage in my making cycle. The first being preparing and pugging the clay bodies ready for making.

First of all I sort out samples of rocks that I am getting low on in powder form - generally around 2 - 5kg, though less if it is a particularly rare rock, and up to 10kg if it is one that I use regularly. If the rocks are in large pieces I will break them up into more manageable pieces with a steel mallet.

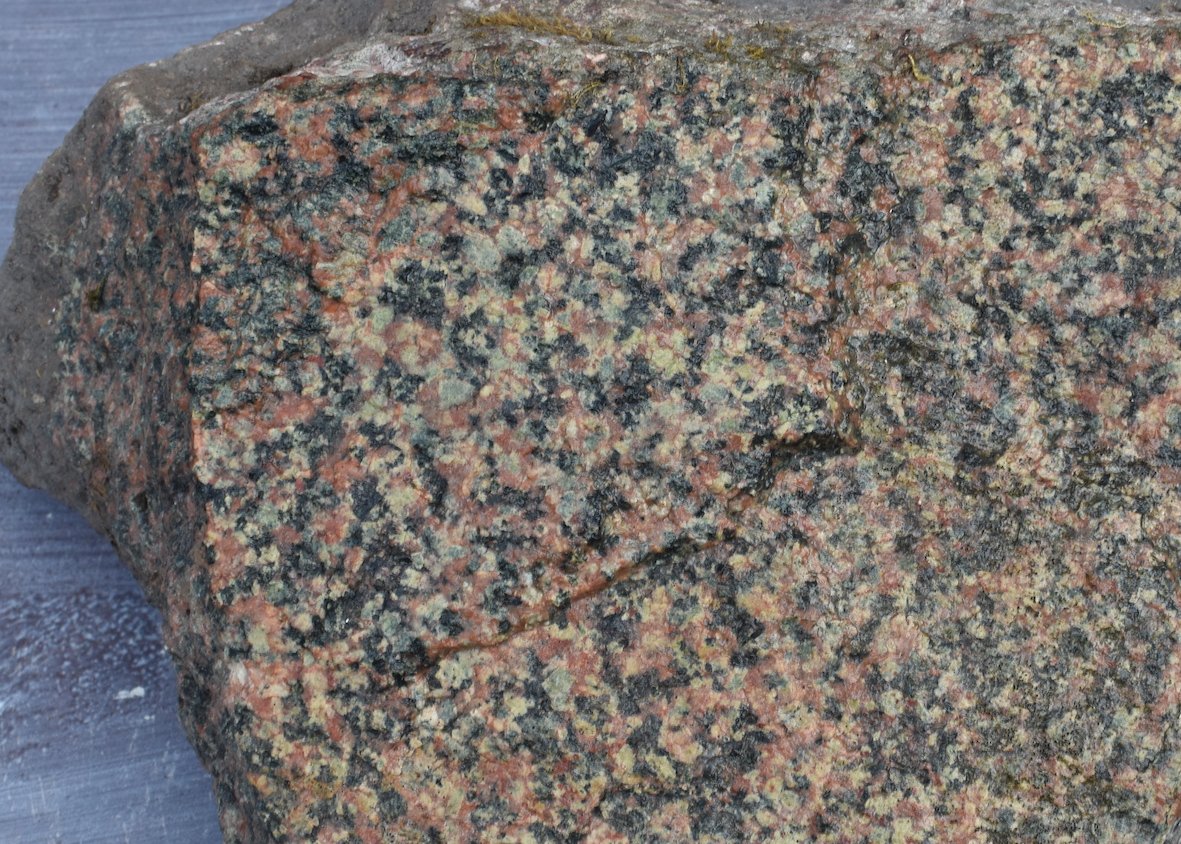

The next stage depends on what type of rock I have to prepare. Some, like the ones shown here, benefit from calcining. This involves heating them to above red heat and allowing them to cool down. I generally put them on the floor of the kiln in a normal bisque firing. This is particularly useful for rocks with big crystals like the granite shown here. The pale white/clear crystals are quartz and these expand and contract at a different rate to the others, on heating. As a result, when you take the granite out of the kiln, it can often be crumbled by hand into its individual crystals.

Other rocks that benefit from calcining are granodiorite (left) and diorite (right). These rocks, like gabbro have a coarse crystal structure that breaks up on heating.

Other rocks, have to crushed to a powder without calcining, as it has no effect, such as with the quartz to the left. the volcanic tuff (right) has such a fine crystal structure that heating makes no difference in its hardness, while clay (far right) will just get harder.

I will go into more detail about this in my forthcoming book, Rock Glazes Unearthed.

I found what I think is malachite while walking through a desert in the form of very small pebbles. I crushed them with a heavy hammer and put them in commercial clear glossy glaze. I know that malachite can be toxic, but once it is encased in clear glaze and fired, would that make it safe to put on the outside of a cup? Would you use such a material? Thanks much for any advice.

Hey, if the glaze is formulated correctly the copper should be locked into the silicate glass, if your firing to high temp that helps too…. If not it can leach, though malachite wouldn’t be leaching it would be a copper oxide it transformed into during firing… still toxic.

I make glazes and my stoneware out of all native stuff here in California (kaolin deposits, fireclay deposits, and granite pegamtites, etc)

Great article about the lesser known granites and stuff like the gabbro and diorite, hard to find glaze info on those. I think gabbro contains calcium feldspar too, which is a great source of CaO but never ever mentioned in ceramic circles